How Much Does It Cost To Get An Arcade Stick Repaired

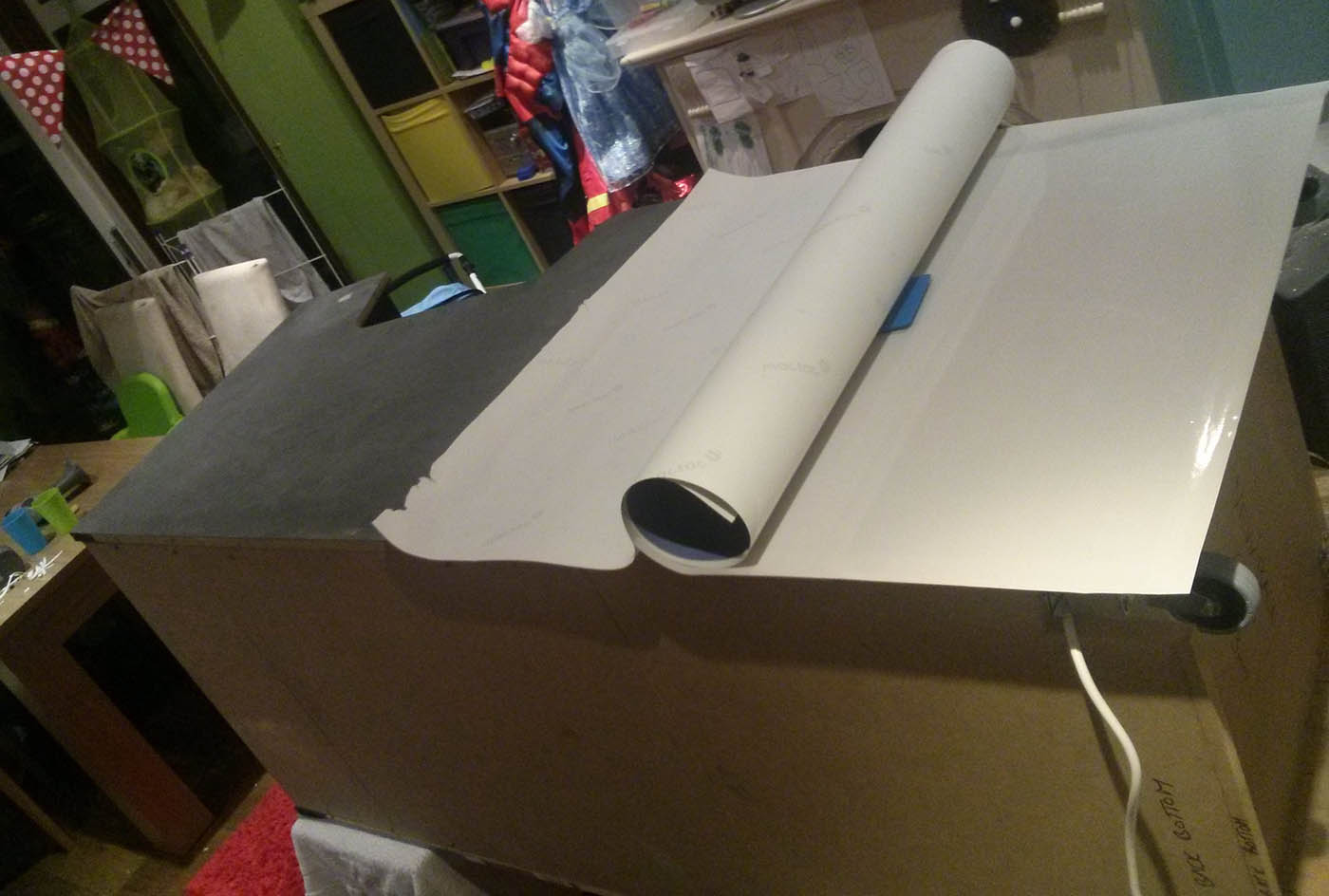

After making the artwork the next question was where to get the vinyl stickers printed. I was always thinking I was going to get the vinyl printed at GameOnGrafix.com in the U.s.. They are arcade artwork specialists and everyone seems to use them. They're also considerably cheaper than about UK vinyl printers then information technology still makes sense even after y'all add on postage from the States. The master reason I didn't employ them, however, was that I was belatedly in getting my artwork finished. I had a deadline of getting my cab finished for my 40th altogether party and I simply started to worry about the aircraft time from the US. Who knows if information technology would be held at customs for whatever reason or anything. In the end I chose to look for a printer in the UK equally I didn't want to miss my deadline. I was struggling though because a lot of them are very expensive and likewise don't accept experience doing arcades, so I wasn't certain they would use the correct material or weight etc. I reached out to the Uk VAC forums for help and inside nearly 30mins someone recommended some other forum member to me: Olly from Arcade Art Shop, known as muddymusic on the UKVAC forum. He seemed to provide an arcade vinyl printing service himself and everyone on the forum used him. I contacted him on the forum right away, at about 11pm, and he replied in well-nigh 10mins proverb he could do it, and offered a very good toll. A full lifesaver. He delivered the goods in time and they looked smashing.

Now I had the vinyl, and had spent then much coin on information technology, I was very nervous about applying it to my cab. I'd heard lots of scare stories about them being hard to use and people having nightmares with air bubbling. To be completely honest though I had no issues at all. I'chiliad not sure if I was lucky or if the vinyl I got was heavier than normal or something. It just worked very well.

If y'all look online in that location are several dissimilar ways people suggest how to utilise the vinyl. You tin can mask it downwardly in the middle and then work your way outwards, you tin can first at one finish and do the full length in one direction, yous can get a squeezy bottle of water to spray downwardly to make the vinyl slightly moveable etc. Information technology partly depends what kind of size and shape of sticker yous have though. I manifestly had the full side artwork done as one whole sticker and I ended upwards going for the approach of starting at one end. I worked from the bottom and worked my style upward.

Firstly I got the vinyl into identify just by a fleck of judging by eye and also measuring key pieces of artwork and how far they were from the edge. I then used a bit of masking tape to tape it lightly in identify so that it wouldn't move while I did the next fleck. I peeled back the outset 10cm or so from the bottom and so with a Stanley knife I cut away the backing paper that was underneath. I and then applied that bare 10cm of sticker to the lesser of the cabinet. At present that it was attached I took off my masking record and rolled the sticker up, correct downward to the edge of the 10cm that was now stuck. I then reached under the rolled upward bit, approaching from the tiptop end, and peeled back the sticker that way, but about 5cm at a fourth dimension and applied that fleck of sticker. Then peeled dorsum the next 5cm and applied that scrap. And so on until you lot reach the very top of the cabinet. Ane good video that shows this method is the awesome Bob Clagett's video at I Like To Make Stuff.

What I oasis't mentioned nonetheless, however, is the duster. That is how you utilize the vinyl and it's the bit that most people say is actually difficult. Some people just employ a cloth or rag, some use a credit menu, but I thought I would get a proper squeegee, so I got this 1 here from Amazon. Information technology's what yous apply to polish the sticker downward on to the surface and make certain you get any air bubbles out. That's what people say is a nightmare – getting the air bubbles out. But I only really came across two or iii and they were like shooting fish in a barrel to go rid of. Y'all just take to take it nice and tedious and work your mode out from the centre. To be honest I was going quite fast at the terminate. No problems at all.

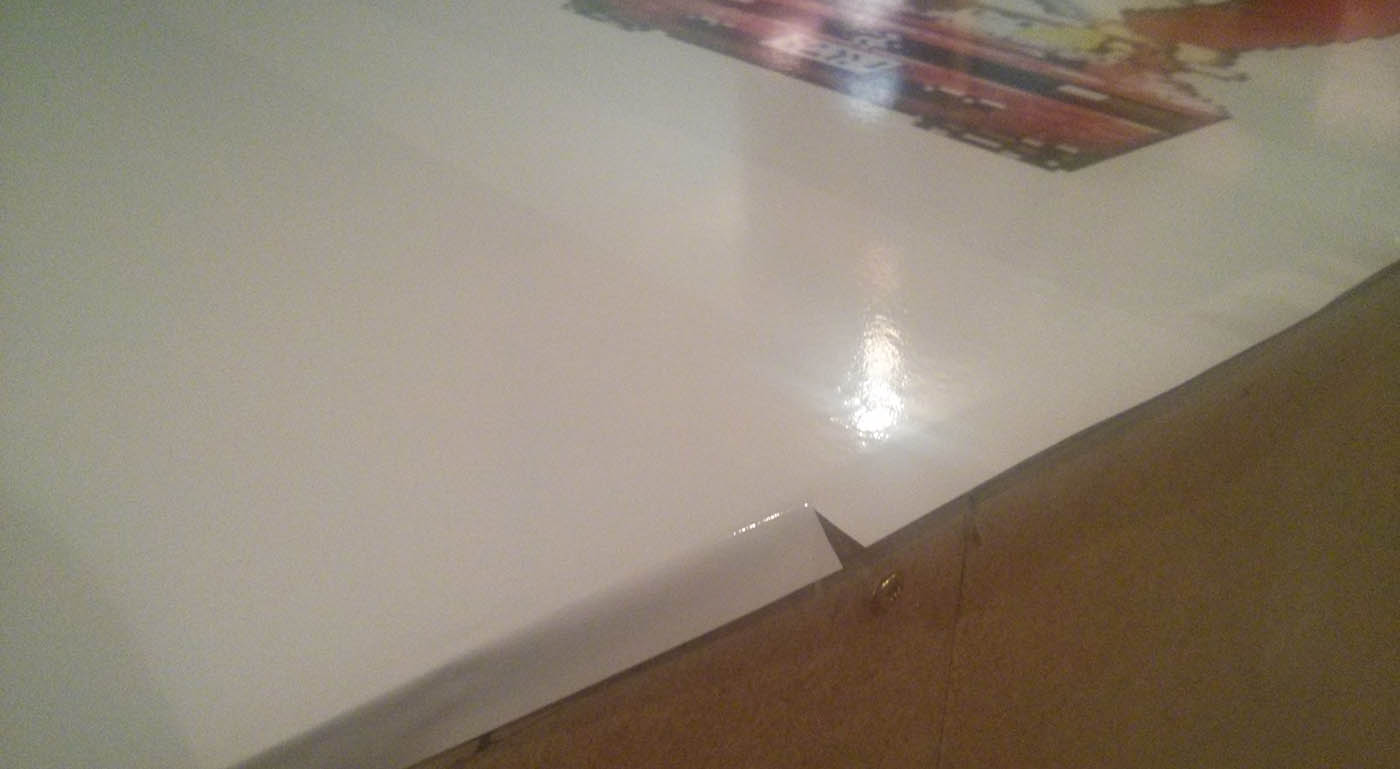

Now that the whole side fine art was downwards on the chiffonier I had to trim round the backlog considering the sticker was a rectangle and the cabinet side isn't. I just had to be careful hither, making sure I knew where the shape of the chiffonier was underneath, feeling it with my hands and trying to leave about 2 or iii cm all around the edges. I used a Stanley knife and it cuts really easily. It just needs patience and care.

Next step was to fold the excess around the edge. On the curves you just have to put piffling nicks in the overhanging sticker every 3cm or and then, to aid it fold over smoothly. Even on the long straight edges like the lesser or the back I even so found I had to put a nick or a cut well-nigh every 10cm or so, just and then that it would stick ok and non leap back under its ain weight. To exist honest there are a few small bits where this chip of sticker has started to come slightly loose around the edges at the back. I'yard sure I could employ some gum or even a small pin in gild to set up that.

Lastly, I didn't want there to exist whatever excess sticker getting down the slot in the border and getting in the way of the t-moulding when I came to add that, so I went circular the whole edge with the Stanley knife and cut whatsoever bits of the sticker that went over the slot. This was a really quick job. I but ran my knife down the slot basically. I then let this sticker stay on the cabinet overnight to make sure it stuck on more than securely, and I used some leap-loaded clamps to help keep the edges in place.

I applied the other sticker the side by side twenty-four hours and I was able to stand up it upwardly and look at the cabinet in all its celebrity. I was over the moon with how it looked and actually happy with all the colours and the quality of the vinyl prints.

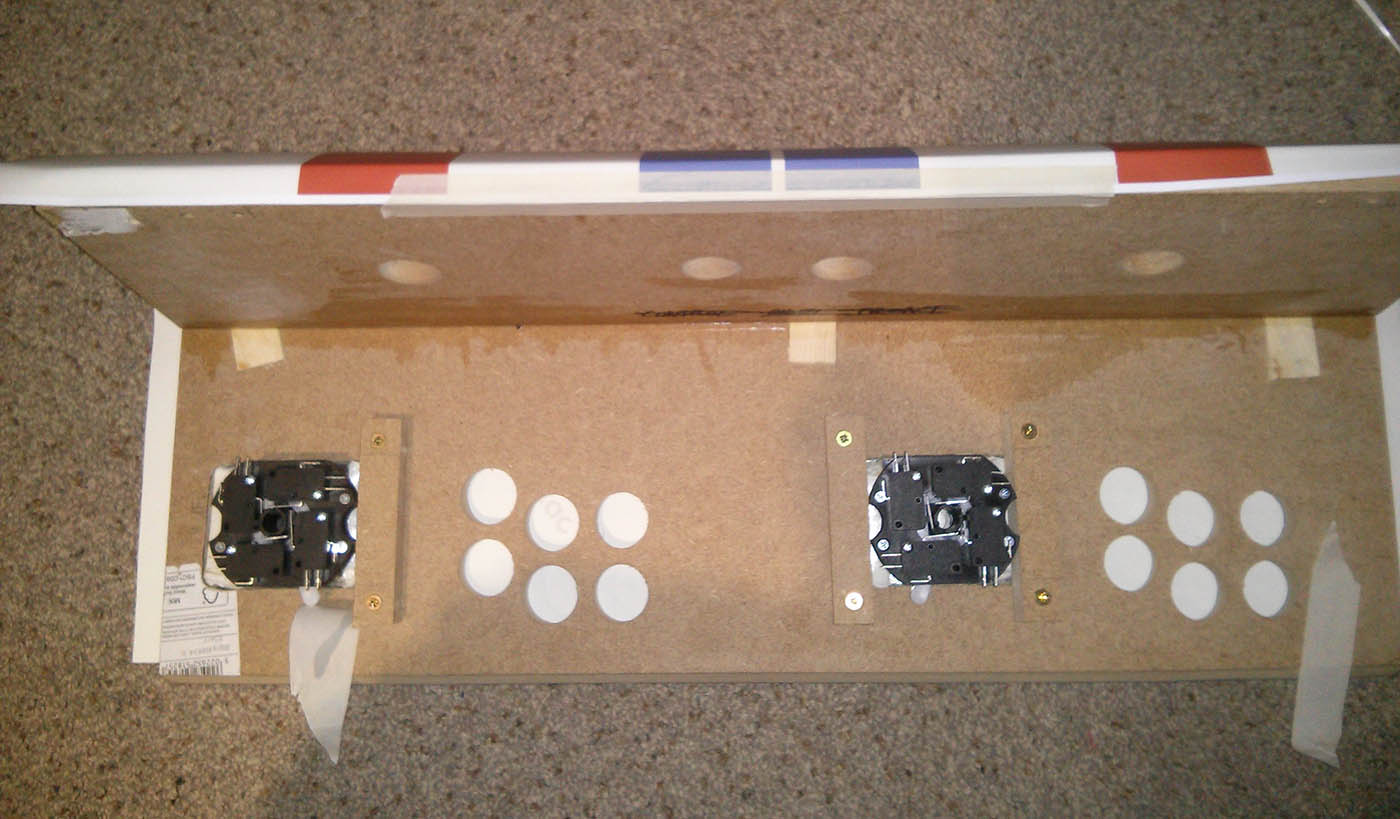

Next up was the control console sticker. This was smaller, so was hopefully going to be easier, but it was actually more awkward to utilise because I had to hold the control panel in my lap, I couldn't really clench it downwards. Information technology besides had to be more than accurate as it would affect how the push placement went. I had tried to exist clever with my control console artwork design as I hadn't been too specific almost where the buttons were going to be. For example if I had wanted a ring of artwork around each push so I would have to take been millimetre perfect not only with the drilling of my holes but also when applying my vinyl so that they matched up perfectly. Instead I chose to but have a horizontal strip of colour and have the buttons sit within this strip, and so I didn't have to exist as accurate in that axis. I as well had buttons on the front that I wanted to be centred inside a thinner vertical strip of colour. One of my slight regrets about this chiffonier build, even so, is that I did brand a flake of a mistake when applying this sticker. I was and so focussed on getting the front buttons centred in the vertical stripe on the sticker that I forgot to check the placement of the main buttons on the horizontal stripe on top of the control panel. I started applying the sticker from the bottom, but by the time I got to the peak I had the middle-sinking realisation that the buttons slightly overlapped the blue stripe instead of beingness correct in the center of information technology. Gutting. No-ane else actually notices it of grade, but I exercise. Every unmarried fourth dimension. I may well have to become the control panel sticker replaced one day anyway (more on that in a future post) and then I'll just be very careful adjacent time.

But all in all I was really pleased with how the vinyl stickers came out and how easy they were to utilize. Information technology totally brings your arcade to life. Information technology is one of the well-nigh expensive parts of the build though, and it's non essential, so information technology's totally up to you whether you simply pigment your sides or become smaller stickers to become on top of painted sides. Lots of ways to save money here.

Hither's a listing of all the posts about my arcade build.

Role i

Role 2 – Decisions

Part three – Chiffonier Design

Role 4 – Command Panel Plans

Part 5 – Initial Questions and Concerns

Part half-dozen – Online Resources

Part 7 – Chiffonier Plans

Part 8 – Buying and Cutting the Wood

Office 9 – Tools and Materials

Part 10 – Building the Cabinet

Part 11 – Building the Control Panel

Part 12 – Sanding and Painting

Part xiii – The Coin Door

Part 14 – Artwork

Part xv – Press and Applying the Vinyl

Office 16 – Adding all the T-moulding

Part 17 – The Television set Monitor

Part eighteen – Making the Bezel

Office 19 – The Marquee

Office 20 – Installing the Electronics

Function 21 – Setting up MAME

Part 22 – Issues to Scout Out For

Part 23 – The Finished Cabinet

Source: https://retromash.com/2016/05/25/building-a-home-arcade-machine-part-15-printing-and-applying-the-vinyl/

Posted by: hallapers1957.blogspot.com

0 Response to "How Much Does It Cost To Get An Arcade Stick Repaired"

Post a Comment